When it comes to creating eye-catching, long-lasting building facades, aluminum tube for facade cladding emerges as a game-changer in architectural design. Zhonglian Aluminum, a seasoned aluminum extrusion manufacturer with 33+ years of expertise, delivers high-quality aluminum tubes tailored for facade cladding-backed by a one-stop production system that covers every step from design to delivery. Our aluminum tubes blend structural strength, aesthetic versatility, and environmental sustainability, making them the top choice for architects, contractors, and property developers worldwide. Whether you're designing a modern commercial tower, a luxury residential building, or a public cultural space, our aluminum tubes for facade cladding are engineered to bring your vision to life.

Products Details

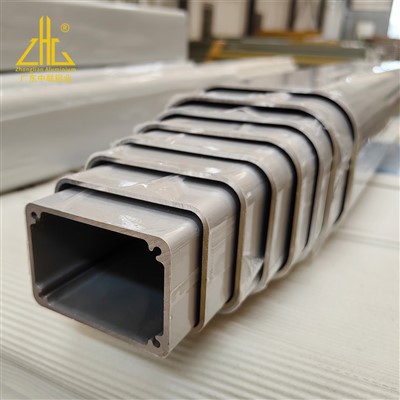

| Item | Aluminum Tube For Facade Cladding |

|---|---|

| Material | High-grade aluminum alloys (6063, 6061, 3003 series) – corrosion-resistant, lightweight, and 100% recyclable |

| Outer Diameter Range | 10mm – 200mm (customizable for small accents or large structural elements) |

| Wall Thickness | 0.8mm – 8mm (adjustable based on load-bearing requirements) |

| Length | Standard 3m – 6m; custom lengths up to 12m (reduces on-site joints) |

| Surface Treatments | Anodizing, powder coating, PVDF coating, wood grain transfer, brushed finish |

| Fire Rating | EN 13501-1 Class A2 (non-combustible, safe for high-rise facades) |

| Weather Resistance | Withstands -40°C to 80°C, UV radiation, heavy rain, and saltwater corrosion |

| Application | Commercial building facades, residential exteriors, public spaces, retail storefronts |

Standout Features

Our aluminum tubes are designed to address the most critical needs of facade projects, combining performance and design flexibility:

- Exceptional Durability: Resists rust, corrosion, and fading even in harsh environments (e.g., coastal areas with salt spray or industrial zones with pollutants). Unlike steel tubes, they require no anti-rust treatments, reducing long-term maintenance costs.

- Lightweight Design: Weighs 70% less than steel and 50% less than copper, minimizing structural load on buildings. This makes them ideal for retrofits or high-rises where weight is a critical constraint.

- Structural Strength: Despite their light weight, our aluminum tubes (6063 series) offer high tensile strength (up to 210 MPa) and can withstand wind pressures up to 2.4 kPa-meeting global building codes for facade safety.

- Design Versatility: Available in round, square, rectangular, or custom cross-sections (e.g., triangular, hexagonal) to create unique facade patterns (e.g., grid, vertical slats, curved screens).

- Thermal Performance: When paired with insulation inserts, our aluminum tubes reduce heat transfer by 20–30%, improving the building's energy efficiency and lowering heating/cooling costs.

Versatile Applications Across Building Types

Our aluminum tube for facade cladding adapts to diverse architectural styles and project scopes:

√ Commercial Buildings: Office towers, shopping malls, and hotels use aluminum tube facades for a modern, sleek look. Vertical or horizontal tube grids create depth while allowing natural light to enter.

√ Residential Projects: Luxury homes and apartment complexes use aluminum tubes for facade accents (e.g., balcony railings, entryway screens) or full facades, adding curb appeal and value.

√ Public Spaces: Museums, airports, and train stations use custom-shaped aluminum tubes to create iconic, artistic facades that reflect the building's purpose.

√ Retail Storefronts: Boutique shops and restaurants use perforated aluminum tubes to balance visibility and privacy, while adding a unique brand identity.

√ Coastal Properties: Our marine-grade aluminum tubes (with anti-corrosion coatings) resist saltwater damage, making them perfect for beachfront hotels and homes.

Premium Surface Treatments for Aesthetics & Protection

Wood grain is the most popluar color to enhance the look and longevity of aluminum tube facades. Our advanced wood grain transfer technology delivers an ultra-realistic, high-definition wood appearance that mirrors the natural texture, grain patterns, and color variations of real wood species-including oak, teak, walnut, pine, and mahogany. The process involves applying a high-quality wood grain film to the aluminum tube surface, followed by heat treatment to ensure the pattern adheres firmly, and a protective topcoat to enhance durability. Unlike real wood, this finish is resistant to rot, mold, termite infestations, and warping-even in humid or rainy climates. It also eliminates the need for regular staining or sealing, reducing maintenance efforts. Perfect for residential facades aiming for a warm, rustic-modern aesthetic, as well as commercial spaces like boutique hotels, cafes, or retail stores that want to create a cozy, nature-inspired atmosphere without sacrificing the strength of aluminum. Available in both light and dark wood shades, and can be paired with matte or semi-gloss topcoats to match specific design preferences.

A variety of types and styles of aluminum extrusion profiles can be customized. ZHONGLIAN offers a variety of aluminum finishing services and options allowing you to perfectly customize your project. Aluminum finishes can give your extrusions a chic, professional look not only improving the aesthetics, but also the performance.

- Anodizing: Creates a hard, scratch-resistant finish in natural metallic tones (silver, bronze, black). Ideal for modern facades that require a subtle, industrial look.

- Powder Coating: 150+ color options (RAL/Pantone matching) with a matte, glossy, or textured finish. Resists chipping and fading, making it suitable for high-traffic areas.

- PVDF Coating: Premium fluoropolymer coating that offers superior weatherability-retains color for 25+ years even in sunny, humid climates. Mandatory for exterior facades in regions with intense UV exposure.

- Brushed Finish: Creates a subtle, linear texture that hides fingerprints and minor scratches. Popular for commercial facades where a clean, understated look is desired.

End-to-End Customization: Tailored to Your Project

At Zhonglian Aluminum, we understand that every facade project is unique. Our factory custom service ensures your aluminum tubes fit perfectly:

- Cross-Section Customization: Design custom shapes to create a one-of-a-kind facade. Our in-house mold shop can develop new extrusion dies in 10–14 days.

- Size Flexibility: Adjust outer diameter, wall thickness, and length to meet structural requirements. For example, 20mm diameter tubes for decorative accents or 150mm diameter tubes for load-bearing facade elements.

- Color Matching: Exact color replication using RAL or Pantone codes to align with your brand guidelines or architectural palette. We provide physical color samples in 3–5 days for approval.

- Perforation & Cutting: Add custom perforation patterns (e.g., circular, square, decorative motifs) for ventilation, light diffusion, or privacy. Precision cutting ensures tubes fit seamlessly with other facade components.

- Assembly Kits: Provide pre-cut tubes with pre-drilled holes and mounting hardware, reducing on-site installation time by 40%.

Precision CNC Machining for Perfect Fit & Function

Our advanced CNC machining capabilities ensure every aluminum tube meets the highest standards of accuracy:

- Precision Cutting: Tolerance of ±0.1mm for clean, straight cuts-critical for creating uniform facade grids.

- Drilling & Tapping: Pre-drill holes for mounting brackets or connectors, eliminating the need for on-site drilling (which can damage the tube's surface treatment).

- Bending & Curving: Create smooth, consistent curves (up to a 1m radius) for curved facades or circular building designs. Our CNC bending machines ensure no kinks or deformities.

- Threading: Add internal or external threads for easy assembly of tube sections, ideal for large facade projects that require modular installation.

- Deburring: Remove sharp edges from cut tubes to ensure worker safety during installation and prevent damage to other facade materials.

Rigorous Quality Control: Ensuring Zero Defects

We maintain strict quality control throughout the production process to deliver flawless aluminum tubes for facade cladding:

- Raw Material Inspection: Test aluminum ingots for purity, strength, and chemical composition (only 6063/6061/3003 series are used).

- Extrusion Monitoring: Track temperature (550°C–580°C) and pressure during extrusion to prevent cracks, warping, or uneven wall thickness.

- Surface Treatment Testing: Conduct adhesion tests (cross-cut test), color accuracy checks (spectrophotometer), and corrosion resistance tests (salt spray test for 1,000 hours). For wood grain finishes, additional tests include abrasion resistance (to ensure the pattern doesn't wear off) and color fastness (to verify resistance to UV fading).

- Dimensional Verification: Use laser measuring tools to check outer diameter, wall thickness, and length against custom specifications.

- Structural Testing: Perform tensile strength and compression tests to ensure tubes meet load-bearing requirements.

- Fire Safety Certification: Test tubes to EN 13501-1 Class A2 standards to confirm non-combustibility.

- Weather Resistance Testing: Simulate extreme weather conditions (UV exposure, rain, temperature cycles) to ensure long-term performance.

- Final Inspection: 100% visual check for scratches, dents, or surface defects-including verifying the uniformity and realism of wood grain patterns-before packaging.

Secure Packaging & Global Delivery

Global Customer Testimonials

Why Choose Zhonglian Aluminum?

As a 33-year-old direct aluminum factory with 100,000㎡ production space, 25 extrusion lines, and 50,000 tons annual capacity, we offer unmatched benefits compared to typical suppliers:

| Advantage | Zhonglian Aluminum | Typical Suppliers |

|---|---|---|

| Service Scope | One-stop: Mold Making → Extrusion → Surface Treatment (including advanced wood grain transfer) → CNC Machining → Delivery | Limited to 1–2 steps (e.g., only extrusion or basic powder coating; no in-house wood grain treatment) |

| Customization Speed | Custom molds in 10–14 days; Production in 7–10 days (including wood grain finishes) | Custom molds in 25–30 days; Production in 20–30 days (wood grain finishes may require outsourcing, adding 10+ days) |

| Quality Control | 8-step inspection (raw material to final product) – including specialized checks for wood grain finish adhesion, realism, and durability | 2–3 basic checks (only final inspection; no dedicated testing for wood grain finishes) |

| Certifications | 6+ global certifications (CE, TUV, SGS, RoHS, ISO, KS) – including SGS verification for wood grain finish performance | 1–2 basic certifications (e.g., only CE; no certifications for wood grain finish quality) |

| Production Capacity | 50,000 tons/year (handles large orders without delays, even for wood grain finished tubes) | 10,000–20,000 tons/year (delays for large projects, especially for specialized finishes like wood grain) |

| Pricing | Factory-direct (15–20% lower than distributors) – no extra cost for high-quality wood grain treatment | Higher prices (includes distributor markups; may charge premium for outsourcing wood grain treatment) |

| Technical Support | 24/7 engineering support for design and installation – including guidance on wood grain finish maintenance and handling | Limited support (only during business hours; no expertise in wood grain finish care) |

Ready to Elevate Your Facade with Aluminum Tubes?

Whether you're designing a small residential accent or a large commercial facade-especially if you want the warmth of wood without the maintenance-Zhonglian Aluminum's one-stop service ensures your aluminum tubes are delivered on time, on budget, and to your exact specifications. Our team of engineers and designers will work with you to optimize your facade design, including helping you select the perfect wood grain finish to match your vision.

[CTA] Get Your Free Custom Quote & Wood Grain Finish Sample Today | Contact Our Aluminum Tube Experts

Hot Tags: aluminum tube for facade cladding, China, manufacturers, suppliers, factory, customized, wholesale, cheap, made in China