We are a professional aluminum profile manufacturer and supplier with 30 years of factory extrusion, surface treatment, and CNC processing experience. If you are looking for long-term aluminum supplier, trust me! You have found the perfect business partner.

We kept helping develop tailor made products to meet customers’ unique demand, especially those require CNC hole punching, screwing, milling, precision cutting, piece powder coating and anodizing.

What's more, we can realize professional customization according to your design drawings or samples, if our anodized aluminum electronic equipment enclosures are not suitable for you, we can extruded according to your designs.

New customers will have the best price discounts. Feel free to contact us anytime!

Products Profile

Anodized aluminum electronic equipment enclosure is a type of enclosure made of aluminum and processed by anodizing. The anodizing process is an electrochemical process that thickens and toughens the naturally occurring protective oxide layer on aluminum. This enhances the corrosion resistance and durability of the aluminum, making it ideal for use in electronic equipment enclosures.

Basic Information

|

Product Name |

Anodized Aluminum Electronic Equipment Enclosure |

|

Aluminum Alloy |

1000 series, 200 series, 3000 series, 5000 series, 6000 series, 7000 series |

|

Temper |

T3-T8 |

|

Shape |

Enclosure, shell, housing |

|

Application |

Electronic, automotive, aerospace, medical, and telecommunication industries, among others. |

|

Surface Treatment |

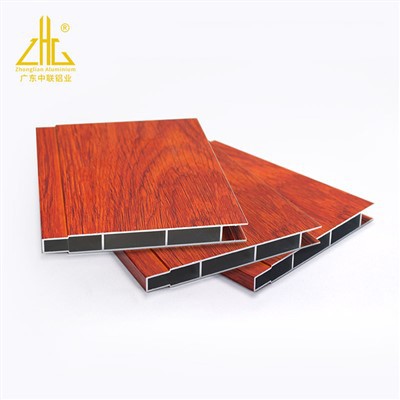

mill finished, anodized, wood grain, power coating, sand blasting, electrophoresis, brushed, polishing, etc |

|

CNC Deep Processing |

cutting, drilling, machining, punching, bending, tapping and so on |

|

Certifications |

CE, ISO, SGS, TUV, ROHS |

|

Samples |

free sample. 1-3 days delivered to you. |

|

MOQ |

500KG for each profile |

|

Delivery Time |

Mold developing and sample conformation is 12-15 days, then production duration is 15-25 days after receipt of deposit from buyer. |

|

Payment Terms |

30% deposit before production, and balance before shipment. |

|

Port |

Shenzhen, Guangzhou, etc |

Products Advantages

1. Anodized aluminum electronic equipment enclosure have excellent resistance to weathering and abrasion, making them ideal for use in outdoor applications.

2. The aluminum construction and anodizing process allow for efficient heat dissipation, which is crucial in electronic applications where heat build-up can cause equipment failure.3.

3. Aluminum enclosures protects electronic equipment from electromagnetic interference (EMI) and radio frequency interference (RFI).

ZHONGLIAN Advantages

1. Experienced factory of more than 30 years, we can make the profile as per your drawing or sample.

2. More than 50000 sizes of ready mold, which largely save your cost and time. Including:

★ tube and pipe, bar, angle shape, window and door, railing, etc.

3. One-stop service of aluminum profile

★ Mold Customization

★ Aluminum Extrusion

★ Surface Treatment

★ CNC Aluminum

Surface Treatment

ZHONGLIAN offers a variety of surface treatment and options allowing you to perfectly customize your project. They are matt anodized, glossy anodized, polishing, mill finish, brushed, powder coating, wood grain, anodized sandblasting and electrophoresis.

Anodized aluminum electronic equipment enclosure, the anodizing process also provides a uniform, hard, and smooth surface that can be colored and dyed to any desired shade. This helps enhance the aesthetic value of the enclosure and makes it attractive for use in different applications.

Other CNC Products We Do

We provide one-stop solution including CNC machining for customer need. Like drilling, punching, welding, milling and precision cutting can be adopted in production.

We offer a complete Aluminum CNC machining service and can produce complex Aluminum parts with 13 different types of Aluminum. Aluminum parts are great for applications that require high strength, corrosion resistance, heat tolerance, low weight, electrical conductivity, and overall versatility.

We are able to machine simple, “as-machined” workholdings to complex, organic geometries with tight tolerances.

With our Aluminum CNC machining services , you can apply up to 13 different post-processing/surface finishing options, including bead blasting, anodizing types, powder coating .

Our Overseas Customers

Until now, we exported to more than 70 countries. Our main market are in Europe, Middle East, Southeast Asia and Australia. We have cooperated with over 15 shipping forwarders who have rich experience to save your cost and time.

We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Ordering Process

We position ourselves as a China-based global aluminum profile solution provider who helps clients develop and design differentiated products, with the aim of helping them win more market share.

In ZHONGLIAN, you can enjoy professional wholesale/OEM/ODM services. From drawing design to manufacturing, our engineering team with over 20-year experience will follow up every detail. Find the product you want on our website. Or send us inquiry to get the specific catalogue pdf.

Hot Tags: anodized aluminum eectronic equipment enclosure, China, manufacturers, suppliers, factory, customized, wholesale, cheap, made in China